Mosaic Sculpture, Alameda, CA

Jean Sweeney Open Space Park

Commissioned in 2018, the completion is scheduled for Spring 2021. Two 16 foot columns of cast concrete are covered in glass mosaic.

The location chosen was on the west end of the new Jean Sweeney Park (near the Webster Tube in Alameda)

December 2019:: Final design for column A

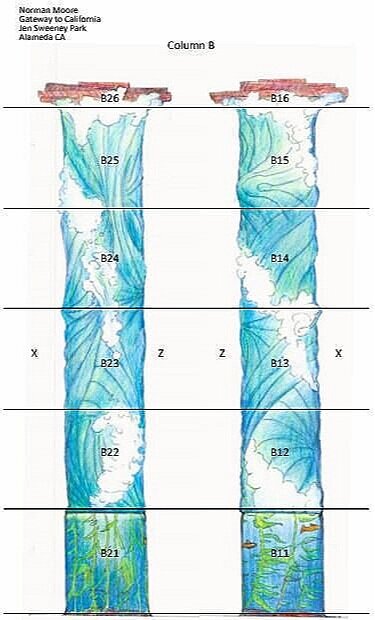

December 2019: Final design for column B

Adding a rise to the top surface for water runoff

Framework in place for inverting capital

Fully flipped capital

Underside of capital complete

The capitals are heavier (about 460lbs) than the side panels (which are 180lbs to 250lbs depending on the design) so I use a gantry crane to move them around.

Lifting inverted section five of column B into place for alignment with capital

Column B, section five on gantry being lifted into place for alignment

Applying mosaic to the underside of column B capital

Applying mosaic to underside of column B capital

November 2020:

Beginning work on the capitals of the columns.

Capital concrete form -upside-down

November 2020: First part of capital for column A cast in concrete, showing exposed stainless steel mesh

November 2020: Constructing form to cast capital for column A

October 2020:

Finished applying mosaic to all 20 vertical panels, that rise up fifteen feet in two columns. Each panel has emerged with its own personality. I have my favorites, but it seems to change.

October 2020: Vertical alignment of mosaic panels

October 2020: Finished panels

October 2020: Applying mosaic to panel B25

September 2020:

Completion of mosaic on all five panels on the first sides of both column A and Column B means work on second sides is ready to start. This will be complicated by the need to align mosaic work side to side as well as top and bottom. Special attention needs to be given to the drawings during this phase of the project.

September 2020: Alignment of panels A22 and A12

September 2020: fitting finished and unfinished panels together

August 2020:

Laying out mosaic on first side of Column B. Finding it difficult to manage the dust in the studio, have to mop the floors every three or four days. It’s not enough to sweep up at the end of each session. It doesn’t help that the sky has turned black with wildfire smoke, looks like the end of the world. I am experimenting with different types of respirators. The N95 has gone missing with Covid19. I ‘m now using a vapor mask, which keeps my glasses from fogging up but is hot to wear.

Studio yard - August 20, 2020

August 2020: Column B, side one mosaic roughed in

July 2020:

Completed applying mosaics to first side of column A. Working six to eight hours a day during the week and just a couple on the weekends. Went backpacking in the Tahoe National Forest for a couple of days but otherwise in the studio every day.

July 2020: Column A, side one mosaic roughed in

Bottom Panel, side one, of Column B

Detail

detail

work on column 2

First level of column A, roughed in, showing the interior

two sections of column A

Mosaic work on first level, column A

Detail

Column A sections laid out

Shop Drawings

constructing form to create sections of column “skins”

Form complete with 304 stainless steel reinforcement in place

Lower section formed, still wet, spindles in place to create sockets for bolting to cast column

Here is the original idea submitted to the city of Alameda for the columns

“Skin” panel section freshly formed and still wet

View of process for creating “skin” for columns. Each section weighs between 140 and 190 lbs

Templates are attached to the form so that each level and side aligns

sections are numbered according to the working drawing for assembly when completed

Using shop crane to lift panel

lifting a “skin” panel into place to apply mosaic

Operating the shop crane

Mosaic studio, working on base section of column A

Unpacking delivery of Egyptian Blue glass from Bullseye

Placing glass in storage bin